Who We Are

THE EARLY DAYS

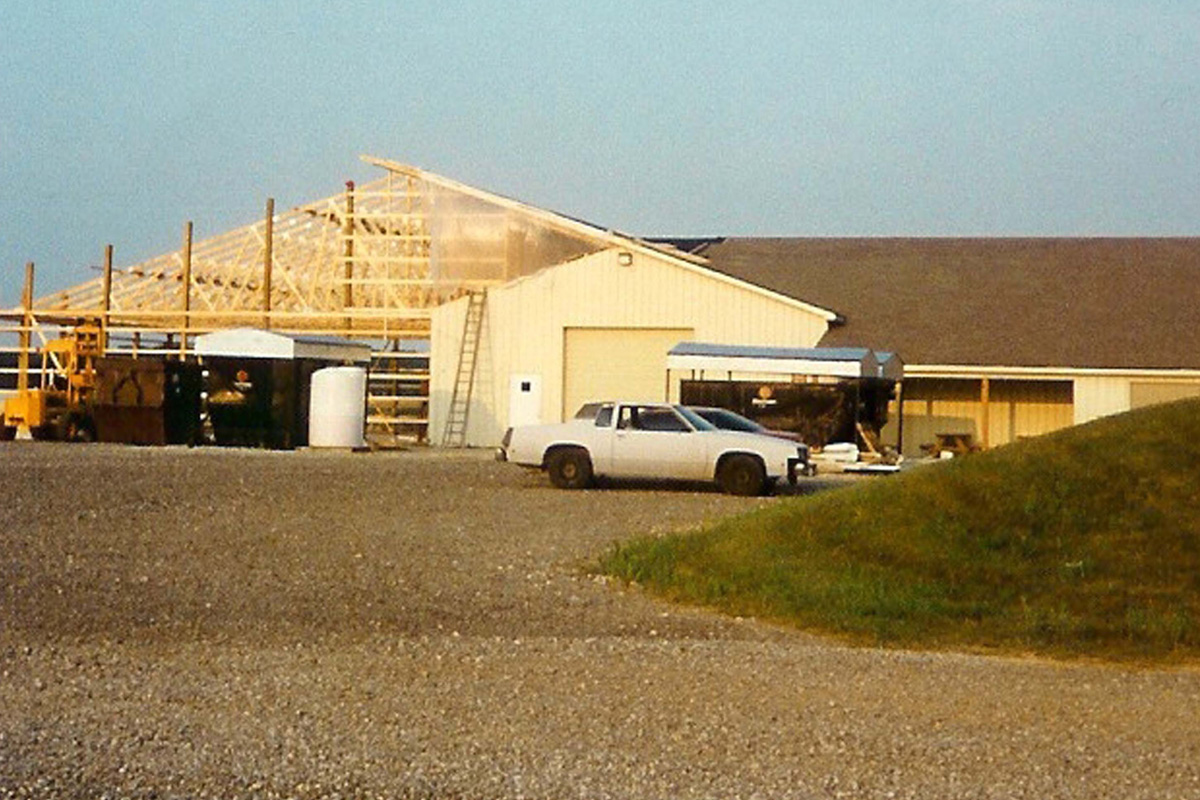

Every company has a story. The Micropulse story began modestly in a 240-square foot section of the family garage of Founder and CEO, Brian Emerick. It was not always easy, but a persistent will and focused tenacity have stood the test of time. To this day, the team at Micropulse continues to deliver value to the employees, customers, and community it serves.

THE VALUE OF ONE

Supplying the highly competitive orthopedic industry doesn’t come easily. An integrated approach to systems, processes, and organizational structure allows Micropulse to meet evolving customer expectations and regulatory requirements. When working with Micropulse, our customers experience high attention to product quality, open and honest communication, and a focus on successful customer outcomes. At Micropulse, our team understands the value of one:

- One owner

- One location with four product lines

- One team providing timely feedback and decision-making

- One source for supply chain coordination

- One industry to serve

- One highly intuitive QMS in accordance with ISO 13485:2016 and 21 CFR Part 820

- One culture serving employees, customers, and our community

- One Mission: Manufacturing excellence through a commitment to quality, integrity, and servant leadership

LOOKING AHEAD

Knowing where we have been provides perspective; knowing where we are going provides opportunity. Micropulse continues to plan for future growth and opportunities with the needs of current and future customers in mind. Building additions, capital equipment expenditures, employee training, and new capabilities must all be considered to meet changing customer needs in a relevant manner.

HISTORY TIMELINE

Located near Columbia City, Indiana, Micropulse has grown and evolved from modest beginnings based on the company’s steadfast commitment to quality, integrity, and innovative approaches that provide customers with immediate and long-term value. We’re proud of our history and the company we’ve built as a team. Learn more about Micropulse’s history by clicking on a year below:

- 1988

- 1990

- 1992

- 1993

- 1995

- 1997

- 2003

- 2005

- 2006

- 2008

- 2014

- 2015

- 2016

- 2018

- 2020

- 2023